YOU ARE HERE: Home > PRODUCTS > Activated Carbon >

Spherical activated carbon

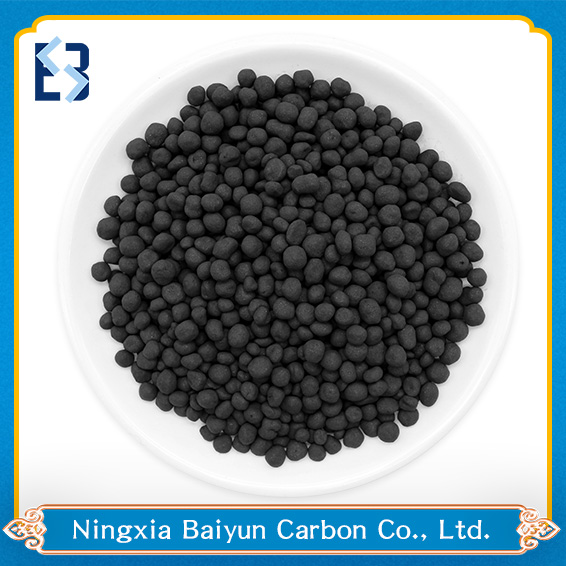

The main raw materials of spherical activated carbon are various wood chips coconut shells or pitches. The raw materials are relatively wide spherical in shape roughly gray-black in color odorless and of course non-toxic. The productio

info@baiyuncarbon.com

Whatsapp+8618695245206

Product Details

Spherical activated carbon

The main raw materials of spherical activated carbon are various wood chips, coconut shells or pitches. The raw materials are relatively wide, spherical in shape, roughly gray-black in color, odorless, and of course non-toxic. The production process is generally carried out by crushing, mixing, spherical, drying, carbonization, and activation. Spherical activated carbon has a smooth surface with black and bright luster, good sphericity, spherical diameter between 0.2-1.2 mm (adjustable), specific surface area (bet) 950-1200 (m2/g), pore volume 0.6-0.75ml /g, the average strength of a single grain can reach 19 Newtons.

This product has low cost and good effect and is especially suitable for air drying, gas-phase drying, and dedicated air compressors.

Spherical activated carbon

Spherical activated carbon is classified by particle size

According to the average particle size classification:

1. 0.2-0.4mm.

2. 0.4-0.6mm.

3. 0.6-0.9mm.

4. 0.9mm and above.

According to the classification of raw materials:

1. Wooden spherical activated carbon.

2. Pitch spherical activated carbon.

Spherical activated carbon characteristics

Like other activated carbons, the main feature of spherical activated carbon is its absorptivity, and its adsorption is mainly divided into two categories: physical adsorption and chemical adsorption.

Physical adsorption mainly uses its porous nature to give it a certain specific surface area, thereby producing its strong adsorption effect.

Chemical adsorption is mainly due to the fact that spherical activated carbon is not only composed of carbon but also has much functional oxygen and hydrogen, such as carbonyl groups, carboxyl groups, phenols, lipids, and other substances. These substances can form chemical bonds with certain substances, and then act as what we call Chemical adsorption.

Of course, spherical activated carbon not only has adsorption characteristics, but also has the characteristics of small particles, high filling degree, good fluidity, high purity, low ash powder, high strength, high wear resistance, and narrow particle size distribution.

Spherical activated carbon adopts a production method using pitch as raw material, and the product performance is stable. In addition, high-quality asphalt is used, the spheroidization process does not use binders, and it is made by maintaining uniform non-melting and activation in a fluid state.

Applications

1. Spherical activated carbon for solvent recovery

There are a variety of organic solvents used in the industry. At the same time as the introduction of excellent products some of the organic solvents are discharged into the atmosphere to form pollution causing profound social problems. To this end a Japanese chemical engineering company developed a solvent recovery device using spherical activated carbon. More than 400 sets of devices have been established in the electrical chemical automotive pharmaceutical and other industries at home and abroad. The energy-saving non-draining solvent recovery and deodorization device have been well received by everyone.

2. Spherical activated carbon for gas treatment of filters etc.

Because of its high purity low dust spherical shape low-pressure loss and strong purification ability spherical activated carbon has been used in the fields of adsorption materials for cleanroom filters in the semiconductor industry and gas treatment in electronic devices.

3. Spherical activated carbon for water treatment

Activated carbon adsorption treatment is a branch of water treatment. With the strengthening of water pollution and related management measures the demand for activated carbon is also increasing. In the activated carbon adsorption treatment the fluidized bed method shows excellent decontamination efficiency. In the fluidized bed method the water purification plant that uses spherical activated carbon as the adsorbent has been effective for more than 10 years. In addition taking advantage of its high purity low dust and abrasion resistance spherical activated carbon is also used in pure water production equipment and drainage treatment equipment.

4. Spherical activated carbon for other applications

Adsorbent for refined chemicals

Adsorption material for catalyst carrier

Capture material for gas analysis

Filling material for gas chromatography

Absorbent materials for shoe soles

Sterilization device materials etc.

Flue gas filter

Related Products

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.