YOU ARE HERE: Home > PRODUCTS > Activated Carbon >

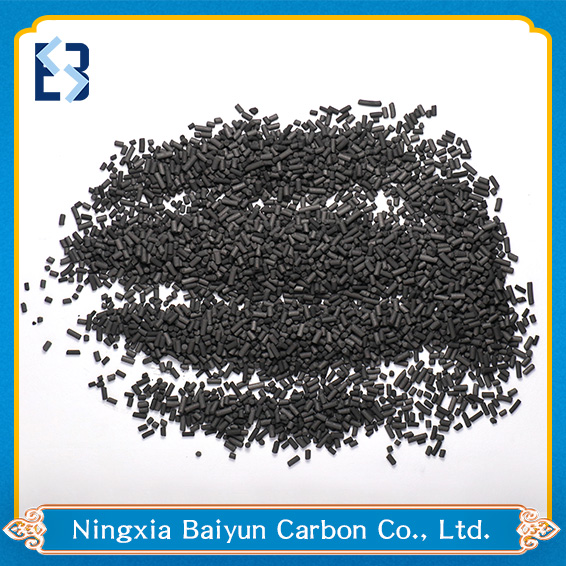

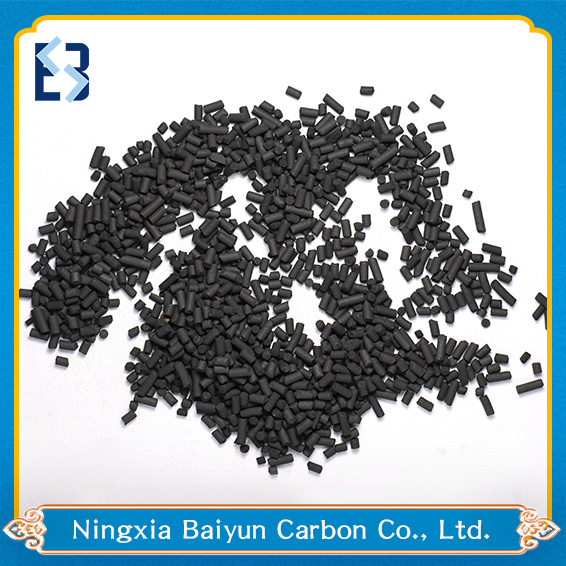

Columnar activated carbon

Columnar activated carbon(Pellet cabon Pelletized activated carbon) is also called extrude activated carbon columnar activated carbon and cylindrial activated carbon. According to different materials pellet activated carbon is classified two types:

Product Details

Columnar activated carbon description

Columnar activated carbon(cabon pellet, activated carbon pellets) is also called extruded activated carbon, columnar activated carbon, and cylindrial activated carbon. According to different materials, columnar activated carbon is classified two types: wood type and coal type. They are the products what made of powdered nuts shell, woods or anthracites added tar as adhesive after carbontization and activatation, and the appearance is black columnar.

Columnar activated carbon classification

They are include coal-based columnar activated carbon and wood columnar activated carbon (wood includes coconut shell and wood).

Wood columnar activated carbon

The coconut shell columnar activated carbon is made of fine wood chips, nuts shell or coconut shell, etc. through crushing, mixing, extrusion, molding, drying, carbonization and activation. Compared with traditional coal-based columnar carbon, it has advantages of lower ash content, less impurities, and higher CTC absort value, etc.

According to the experimental data of Baiyun Carbon Co., Ltd., 4mm activated carbon has a CTC adsorption rate of 60%, not more than 70%, while the produced 4mm wooden pellet activated carbon has a CTC adsorption rate close to 100%.

Coconut shell pellet activated carbon index

| Size(mm) | Moisture(5%) | strength(%) | Ashes(%) | Benzene adsorption rate(%) | CTC adsorption value(mg/g) | Packing density(g/l) | Fire point(℃) | Particle size(mm) |

| 3.0 | ≤5 | ≥95 | ≤7 | ≥35 | ≥80 | 400±20 | 380±30 | φ3.0 |

| 4.0 | ≤5 | ≥90 | ≤7 | ≥40 | ≥90 | 380±20 | 380±30 | φ3.0 |

| 5.0 | ≤5 | ≥90 | ≤7 | ≥45 | ≥100 | 350±20 | 380±30 | φ3.0 |

| 6.0 | ≤5 | ≥95 | ≤7 | ≥35 | ≥80 | 400±20 | 380±30 | φ4.0 |

| 7.0 | ≤5 | ≥95 | ≤7 | ≥40 | ≥90 | 380±20 | 380±30 | φ4.0 |

| 8.0 | ≤5 | ≥95 | ≤7 | ≥45 | ≥100 | 350±20 | 380±30 | φ4.0 |

Coal based pellet activated carbon

The coal-based pellet activated carbon is made of fine anthracite as raw materials, after series processes. And it has the appearance of black cylindrical particles; it has a reasonable pore structure, good adsorption performance, high mechanical strength, easy repeated regeneration, and low cost. For the purification of toxic gases, waste gas treatment, industrial and domestic water purification, solvent recovery, etc.

Coal-based pellet activated carbon index

| Index | unit | 1.5 | 2.0 | 3.0 | 4.0 |

| Iodine adsorption value | mg/g | 500/1050 | 500/1050 | 500/1050 | 500/1050 |

| Carbon tetrachloride adsorption rate | ≥% | 50/70 | 50/70 | 50/70 | 50/70 |

| Moisture | ≤% | 10 | 10 | 10 | 10 |

| Ashes(Burning residue) | ≤% | 8/15 | 8/15 | 8/15 | 8/15 |

| Abrasion strength | ≥% | 80/90 | 90/95 | 90/95 | 90/95 |

| Bulk specific gravity | g/l | 450-650 | 450-650 | 450-650 | 450-650 |

| Particle size | mm | 1.5 | 2.0 | 3.0 | 4.0 |

Columnar activated carbon feature

Columnar activated carbon advantages:

Coconut shell columnar activated carbon has advantages of lower ash content, less impurities, gas phase adsorption value, and higher CTC adsorption.

Applications

Related Products

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.